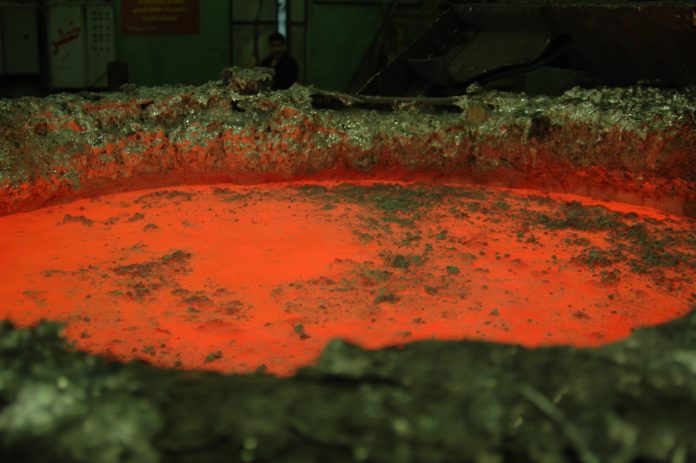

At regular intervals, molten primary aluminum tapped from pots is transported to the Cast House where it is alloyed in holding furnaces by the addition of other metals or elements, according to the request of the customers, cleaned of oxides and gases, and then casting into ingots . Applying of different holding and homogenizing furnaces vertical and horizontal D.C machinaries the ingots and logs are converted to all types of casting and (wrought) workable aluminium to various AA,GB,ISO Din standards .

Iralco Cast House

Iralco 50,000 Tons of Billet Cast House (long length )

Enjoying different furnaces such as, holding , re- melting , homogenizing ,vertical and horizontal casting machines(DC) and pig machines ,is able to produce all kinds of aluminum alloys according to the request of the customers and AA.,GB,ISO ,…standards.The products of the this workshop are produced as follow:

1. (Wrought )Workable alloys in slab and T.Bar forms by the D.C.direct chill method.

In alloying process, the melt quality process, includes, Fluxing, Degassing, Grain refining, Filtration, Skimming and so on … regarding the type of alloy and customers request performed, and is controlled by the quality control Q.C unit.

2. Casting products in the form of T.bar. 1000 and 50 pounds(Lb)

The nominal capacity of the workshop is 180,000 tons (py) which after Q.C.control, cutting and packaging, is delivered and distributed to the customers and down stream industries.

The new casting workshop has a capacity of 50,000 tons of billet(py), which includes two 30 and 50 tonne rotary furnaces with magnetic mixer, the equipment of melt quality treatment includes. (hydrogen degassing, automatic germination injection, melt filtration chamber), a billet vertical casting machine with cooling water system, two monolithic furnaces, a cooling chamber and an automatic catting and packaging machine, it was inaugurated on April 1996 about 4200 tons monthly and 50,000 tons (py) of aluminium billet to domestic and foreign markets are produced.

the advantages of this new method long length, billet production are, good quality at the final level of products, homogenization of alloy structure, reduced production costs and energy consumption, replacing billet exports instead of ingots.